HOW TO SELECT YOUR BANDSAW BLADES

STEP 1

ANALYZE THE SAWING APPLICATION

Machine:

For most situations, knowing the blade dimensions (length x width x thickness) is all that is necessary.

For example: Name of the product Length x width x thickness tooth per inch

WIKUS PRIMAR® 4860 mm x 34 mm x 1,07mm 3/4 TPI

Material:

Find out the following characteristics of the material to be cut.

- Grade

- Hardness (if heat treated or hardened)

- Shape

- Size

- Is the material to be stacked (bundled) or cut one at a time?

Other customer needs:

The specifics of the application should be considered.

-

Production or utility/general purpose sawing operation?

-

What is more important, fast cutting or tool life?

-

Is material finish important?

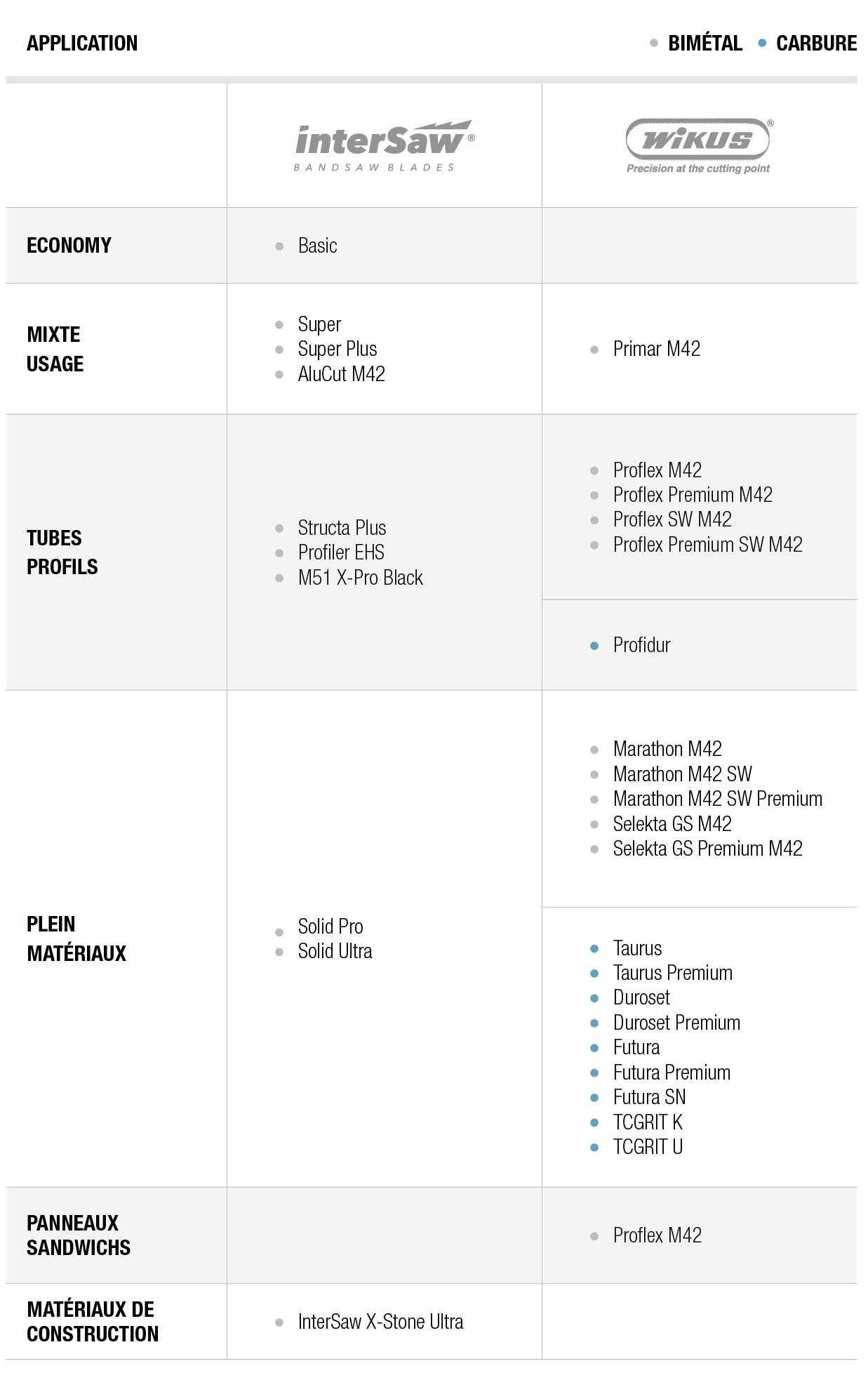

STEP 2

DETERMINE WHICH PRODUCT TO USE

Use the charts

- Find the material to be cut in the top row

- Read down the chart to find which blade is recommended

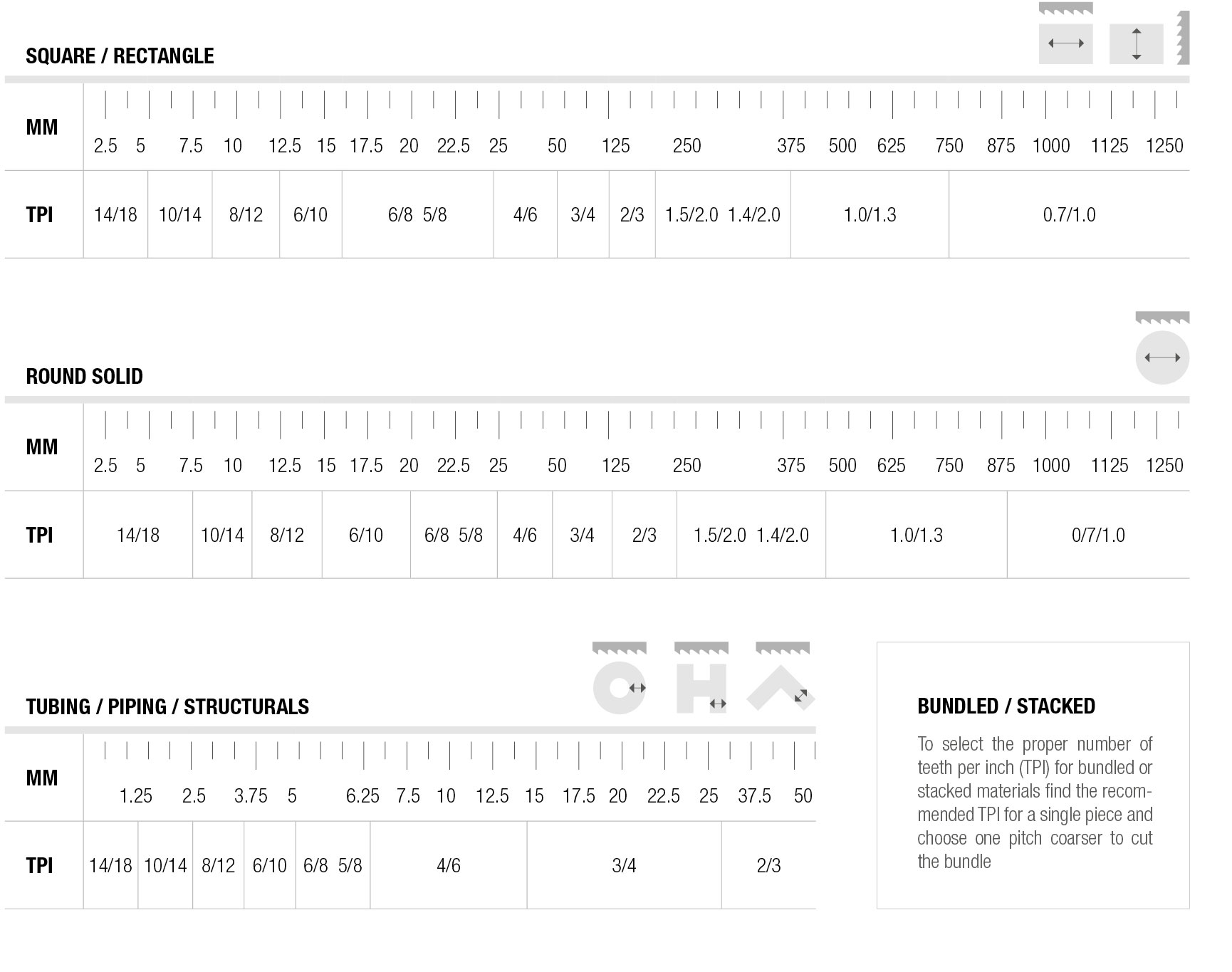

STEP 3

DETERMINE THE PROPER NUMBER OF TEETH PER INCH (TPI)

Use the tooth selection chart

-

If having difficulty choosing between two pitches, the finer of the two will generally give better performance.

-

When compromise is necessary, choose the correct TPI first.

-

A general rule for bundles: Determine the correct TPI for one piece, and choose one pitch coarser for the bundle.

STEP 4

ORDER INTERSAW SAWING FLUIDS AND LUBRICANTS

For better performance and a longer lifespan of your saw blade, we recommend using a high-quality coolant. In our online shop, you will find high-quality coolants suitable for cooling pumps or micro-dosing systems.

STEP 5

INSTALL THE BLADE AND FLUID

STEP 6

BREAK IN THE BLADE PROPERLY

Depending on the hardness and dimensions of the materials you wish to saw, you'll need to break in certain types of bandsaws.

Click here and discover the different steps !

STEP 7

RUN THE BLADE AT THE CORRECT SPEED AND FEED RATE

POSSIBLE CAUSES OF DEFECT BLADES

The tips mentioned above are key factors for a greater blade durability.

Should you experience any problems, click here and find out the most common causes.